Prices: Subject to change without notice

Delivery: Three weeks to ship for any of our existing Printer or System cases.

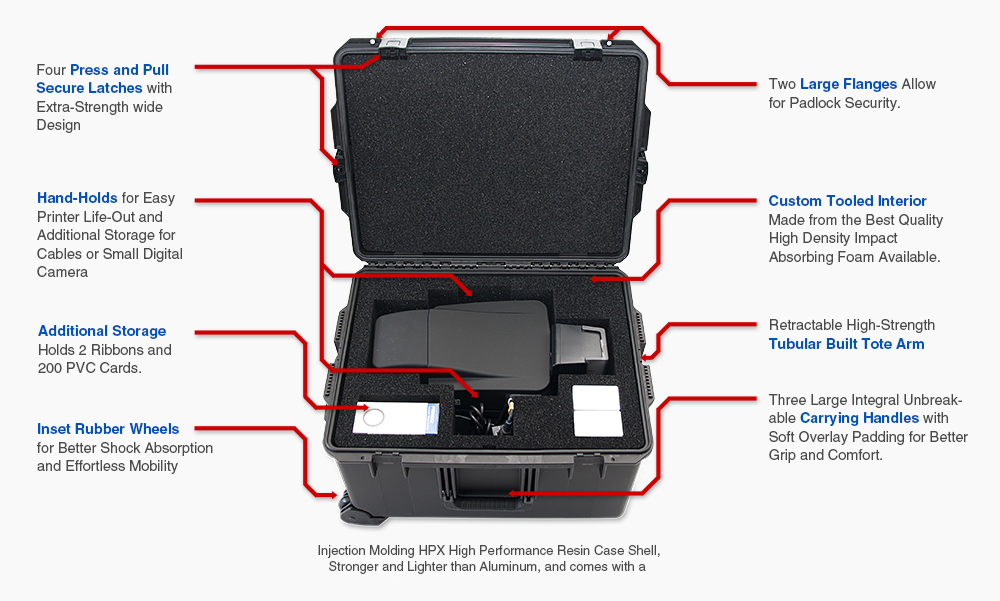

Standard Printer Cases: Only standard printer cases are listed on our website (printer and two storage compartments).

System Cases: Please call before ordering to discuss specific requirements and confirm pricing.

Colors: Some colors have been discontinued for certain case models, please call before ordering to confirm availability.

New Case Designs: Four weeks to ship typically when modifying an existing, or creating a new case design.

All case designs are property of BadgePlus, Inc.

QUESTIONS ABOUT CASES

Printer Transport Cases are custom made to order. Returns are not accepted unless BadgePlus determines that an error has been made on our part. Upon receiving a BadgePlus Printer Transport Case, the recipient has 5 working days to inspect and contact BadgePlus as to any discrepancies with the order.

The cases are made out of a Polypropylene copolymer material that is light weight, durable and highly chemical resistant.

The cases will withstand temperatures from -10°F (-23.3°C) to +210°F (98.9°C).

Due to the nature of the polypropylene being chemically inert, very little will attack the material. That also means that very few adhesives and paints will adhere satisfactorily. For an adhesive, we have found that 3M’s DP-8005 two-part adhesive works very well with our case material. It has also been reported that “Shoe Goo” works very well. For paint, Krylon has a product out called Fusion that they claim will adhere to polyolefin-based materials like polypropylene.

RoHS, or “Restriction on Hazardous Substances” – RoHS specifically bans or restricts the use of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated biphenyl ethers (PBDE). At the July 1, 2006 implementation of the RoHS provisions, Pelican cases will not contain the banned or restricted materials and will therefore be RoHS compliant. NOTE: Directive 2000/95/EC of the European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment – is aimed at reducing the hazardous materials content in electronic products as well as increasing the recycling efforts for these products.

Pelican cases have been tested to MIL-C-4150J, ATA 300, Def Stan 81-41/STANAG 4280 and Ingress Protection (IP). Certificates are on file and copies are available upon request. Please note that for deep submersion internal bulkheads should be installed.

Yes, the cases are water resistant. There is an o-ring in the lid and a Gore-Tex® membrane in the pressure equalization valve that keep water out of the case.

The Pressure Equalization Valve is a simple device. It consists of a housing with a hole through it that is covered with a thin Gore-Tex® membrane. According to the Gore™ tech sheet: “The microporous expanded polytetraflouroethylene (ePTFE) membrane continuously allows the free passage of gases and vapors, equalizing the pressure differential between the enclosure and ambient before it builds to the point that a seal is compromised. Water, dust and dirt are repelled by the hydrophobic membrane, thereby protecting expensive and sensitive electronics.

The o-ring is made of EPDM or Ethylene Propylene Diene Monomer. It is well known for its excellent ozone, weathering and aging resistance. It also has excellent water and steam resistance, maintains its flexibility at low temperatures, features excellent resistance to alkalis, acids and oxygenated solvents and is very color stable. (It is not recommended for resistance to oil, gasoline and hydrocarbon solvents.) EPDM is found in a wide range of applications and is excellent for use outdoors.